Liquid Manure Treatment

Optimize liquid manure treatment with Penergetic g

Boost the aerobic breakdown process in your swine or cattle slurry.

Economical liquid manure technology that provides a great return on investment producing better soil, crops and groundwater.

Reduces causticity for better compatibility with plants and soil microbes

The benefits of Penergetic g in for your liquid manure

- Eliminates unpleasant ammonia and sulphur odors

- Controls crust and/or sediment layer formation

- Causes slurry to become homogenous

- Addresses insects and manure-borne pathogens

- Better for soil and crops while protecting groundwater

- Stabilizes phosphorus and nitrogen levels in the manure

- Reduces requirements for pit agitation

- Modulates methane and foaming

- Reduces causticity for better compatibility with plants and soil microbes

- Reduces the occurrence of harmful insect and insect larvae

- Environmentally friendly and ecologically balanced (OMRI listed)

Transforming Liquid Manure into an Ultimate Fertilizer

The spreading of untreated cattle and hog manure is both extremely costly and has grave, negative soil and environmental consequences.

LIQUID HOG MANURE TREATMENT

- In hog manure; we relieve bottom shelving of solids

- Reduce significantly the ammonia odour both in the barn and when spreading, by converting it to ammonium which is easily stabilized in the soil as available nitrogen

- Tends to relieve light surface crusting thereby mitigating larva and insect pressure

- Relieves jammed hairpins and channels with ease of flow

- Suppresses foaming when filling tankers

- Works equally well in pits under barn, outside storage or lagoons

- Extremely safe and easy to use with huge return on investment

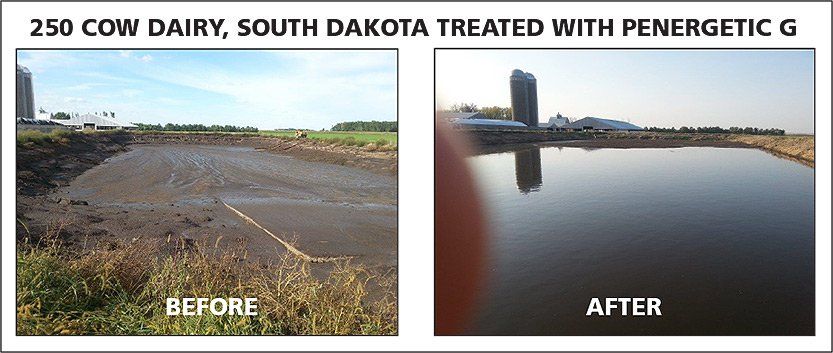

LIQUID CATTLE MANURE TREATMENT

- Substantial relief of surface crust becoming more homogeneous even without agitation.

- Tends to require tremendously less agitation – resulting in huge cost savings

- Transitioning from anaerobic to aerobic liquid manure, nutrients are stabilized, highly available even in non-injected surface application – ( huge odour reduction)

- Works equally well in pits under barn, outside storage or lagoons

- Cattle manure treated with Penergetic g is extremely safe and easy to use with a huge return on investment

Build Healthier, more Vibrant Soil!

01

Stabalizes

02

Reduces

03

Converts

04

Breaks Down

Transforming Liquid Manure Into a Valuable Organic Fertilizer

The Underlying Problems of Putrefaction

Typically, slurry will become a problematic waste product when conversion takes place by means of putrefaction processes. This involves decay under anaerobic conditions, i.e. in the absence of oxygen. Anaerobic conversion of slurry leads to the development of malodorous gases, including hydrogen sulphide and ammonia, and (odourless) methane gas. Also problematic, the odour carriers in manure – indole and skatole (3-methylindole) – attract harmful insects. These insects lay their eggs in the slurry, and the subsequent larvae often remain in the slurry when it is applied on the fields, leading to crop damage and the need to apply pesticides. Furthermore, the valuable substance ammonium nitrogen is lost in the anaerobic slurry, because ammonium is converted into ammonia, through volatilization, and consequently is no longer available as a nutrient for plants.

Oxygen through Aeration or Optimized Decomposition

The conventional method of introducing oxygen into the slurry involves mechanical aeration by means of stirrers or compressors. However, this technical method becomes problematic when dealing with large quantities of slurry which cannot be stirred effectively every day. Floating layers then quickly form, further sealing off the slurry from the oxygen supply and thus strengthening the anaerobic environment. Also, the annual energy costs for stirring/agitation operations can be considerable.

But there is another way! The simple and natural solution to turn slurry into a valuable organic fertilizer involves activating decomposition processes in the slurry which only take place with oxygen. The decomposition processes involve mold fungi, yeasts and many other microorganisms; include several biological processes which are absolutely vital to maintaining a state of equilibrium in nature. Mold fungi very quickly bind any ammonia which is present in the first stage of the decomposition process to form ammonium nitrogen, which is subsequently available to plants as a slow release source of nitrogen. The harmful and unpleasant biogases are also largely eliminated, providing for a noticeable difference in the pit/lagoon and during application. Healthy, decomposed (rotted) slurry thus constitutes an important element of a closed substance cycle management system which benefits the soil, plants, animals and humans alike.

Activating the Sludge

The best solution is a simple method which activates the aerobic bacteria while avoiding the use of external energy and other factors detrimental to the environment. Penergetic g possesses the specific active properties to reactivates the life processes in slurry. The putrefactive bacteria die and the oxygen which is present in the slurry is aerobically activated. An oxygen-producing and breathing biomass quickly arises. The micro algae which develop change the colour of the slurry to dark green and the work performed by the bacteria renders the slurry homogeneous. In the course of time, existing floating layers and sedimentation layers dissolve. As a natural side-effect of these processes, the smell is diminished. Using the decomposed slurry produced with penergetic g enables the quantity of commercial fertilizer used to be reduced.

Dry Manure Treatment

For Optimized Dry Manure Composting and In Barn Use

Improves compost quality

Affordable manure management technology that provides a great return on investment.

Stimulates the conversion of ammonia and increasing humus formation

The benefits of Penergetic k for dry manure management

- Activates the aerobic process for accelerated optimum composition

- Suitable for all manner of compostable materials (e.g. solid manure, plant matter, municipal waste stream)

- Reduces insect pest problems and odours associated with composting

- Limits loss of nutrients (e.g. nitrogen) during composting process

- Contributes to elimination of weed seeds and pathogenic organisms

- Produces more homogeneously consistent nutrient rich humus

- Assists in regulating temperature during composting

- Helps propagate healthy soil fungi and reduces detrimental fungi

- Proven effective at decomposing dead animals

- By promoting a more complete breakdown of manure, helps prevent nutrient overload on fields

- Proven and cost effective approach to composting

Increase Crop Yields through Accelerated Biological Processes